Lead Removal Contractors-- Skilled Professionals for Lead Abatement

Wiki Article

Necessary Tools and Strategies for Reliable Lead Infraction Cleanup

Dealing with lead violations efficiently demands a detailed method that blends the right tools with strategic methods. Simultaneously, the use of specialized cleanup devices, such as HEPA vacuum cleaners and lead-specific cleaning agents, is vital for detailed impurity elimination. Efficient control approaches, consisting of plastic sheet and negative air stress systems, are essential to avoid the spread of hazardous products.Personal Protective Tools

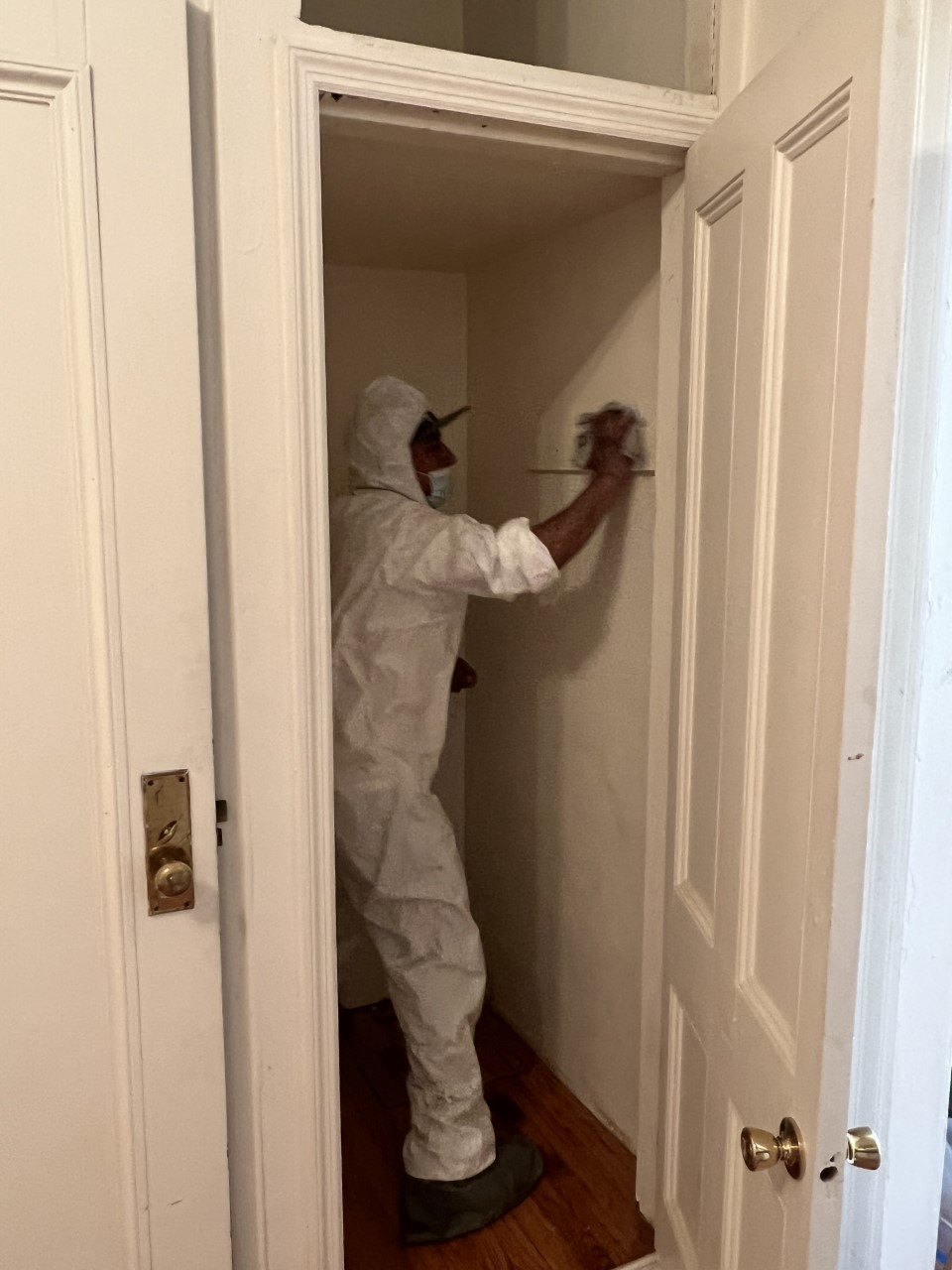

Personal protective equipment (PPE) is an important component in the reliable monitoring of lead contamination clean-up. The crucial PPE for lead cleanup consists of respirators, protective garments, handwear covers, and eye security.Respirators, particularly those geared up with HEPA filters, are indispensable for filtering system airborne lead bits, preventing breathing. Safety clothes, including coveralls and non reusable matches, stops lead dirt from adhering to employees' garments, minimizing the threat of secondary contamination.

Moreover, extensive training on the proper use and maintenance of PPE is vital. Workers need to be informed on donning and doffing treatments to prevent contamination. Regular assessments and replacements of PPE components are required to preserve their safety abilities, making certain a secure and certified cleaning procedure.

Specialized Clean-up Equipment

An additional crucial device is the wet/dry vacuum, which can properly cleanse up both dirt and liquid pollutants. These vacuum cleaners typically feature HEPA filters to give an added layer of safety. Damp wipes or tack fabrics are additionally crucial for surface cleansing; they are particularly made to capture and hold lead fragments, reducing the risk of spreading contamination.

For more stubborn down payments, specialized lead-removal cleaner are called for. These agents are formulated to break down lead bits, making them much easier to get rid of. Scrub brushes with sturdy bristles can aid in this process, especially on rough surfaces where lead dust has a tendency to adhere much more strongly.

Furthermore, encapsulants are utilized to secure lead-contaminated surface areas, stopping the launch of lead dirt. These specialized paints and layers are designed to follow various substrates, providing a long-term solution for lead control.

Reliable Control Approaches

Reliable containment methods are vital in alleviating the spread of lead contamination during cleaning tasks. Implementing robust containment approaches makes sure that lead particles do not move to unaffected locations, thus protecting both employees and the environment (DOH & HPD Lead Violation Removal NYC).

To improve containment, encapsulants can be applied to surfaces that are not being removed or disrupted. additional hints These specialized finishes bind lead dust, lowering its schedule for resuspension. Additionally, all personnel should wear ideal Individual Safety Equipment (PPE), including respirators and non reusable fits, to avoid contamination spread.

Safe Disposal Practices

Making certain safe disposal practices is a vital part in the management of lead contamination cleanup. Correct disposal mitigates the risk of lead coming back the setting and endangering public health and wellness. The primary step is to visit this website identify and set apart lead-contaminated waste from various other materials. Safe control using sturdy, leak-proof containers is vital to prevent spillage throughout transportation.Moving lead waste requires adherence to strict guidelines. Utilizing certified contaminated materials providers makes sure that the products are managed sensibly. Documents, including manifests describing the type and quantity of waste, need to come with shipments to track the waste from the website of beginning to its last disposal location.

Designated dangerous waste disposal facilities are outfitted to deal with lead-contaminated materials safely. These facilities commonly utilize advanced methods such as stabilization, solidification, or chemical treatment to counteract the lead prior to disposal. Landfilling in specialized, lined locations that prevent leachate from infecting groundwater is a common practice for final disposal.

Regular training for employees involved in lead waste disposal is critical to preserve safety requirements and protect against unexpected exposure. By sticking to these techniques, organizations can substantially reduce the environmental and health effects related to lead contamination.

Regulatory Compliance Tips

Following governing compliance is paramount in the successful implementation of lead contamination cleanup. Recognizing and adhering to government, state, and neighborhood regulations makes sure not only the safety and health and wellness of individuals yet additionally the lawful and monetary wellness of navigate to this website the clean-up company. The Environmental Protection Firm (EPA) establishes rigid requirements, such as the Lead Renovation, Repair, and Paint (RRP) Policy, which mandates correct certification and training for contractors managing lead-based tasks.

Compliance begins with a comprehensive analysis of appropriate regulations and regulations. Organizations has to stay upgraded on any legislative adjustments, which can be helped with with routine training sessions and signing up for industry updates. Paperwork is one more crucial compliance element; keeping detailed documents of all activities, consisting of examination records, employee training logs, and disposal materializes, is necessary.

Additionally, engaging with licensed lead inspectors or run the risk of assessors ensures that lead hazards are correctly determined and minimized. Employers must implement the usage of Individual Safety Tools (PPE) and ensure that safety methods are purely complied with. Transparent communication with stakeholders, consisting of employees, clients, and governing bodies, will certainly promote a society of conformity and responsibility, eventually adding to a safer and extra reliable lead cleaning process.

Conclusion

Reliable lead offense clean-up demands the integration of specialized tools and calculated methodologies to ensure safety and efficiency. Individual protective devices (PPE) safeguards workers from direct exposure, while safe disposal practices and rigorous adherence to regulative conformity are important for sensibly handling dangerous waste.Report this wiki page